Table of contents

Role and function of the O-ring for mechanical seals

- Secondary seals: static vs. dynamic (pusher/non-pusher)

- Self-energizing & compression (ISO 3601 groove dimensions)

- Common failure modes: RGD, extrusion, compression set

Material selection for oil & gas

- HNBR O-ring vs. FKM O-ring (temperature, sour service)

- AFLAS® O-ring & FFKM O-ring (extreme chemistry, H₂S/amine/steam)

- AED-resistant O-ring (RGD): when mandatory

Design & installation

- PTFE back-up ring: at high differential pressure/pressure

- Hardness (70-90 Shore A), roughness & lubrication

- Groove design checklist per ISO 3601

Standards & selection: O-ring for mechanical seals

- API 682/ISO 212049 (seals), implications for O-rings

- NORSOK M-710 / ISO 23936-2 & NACE TM0297 (AED/RGD)

Role and function of the O-ring for mechanical seals

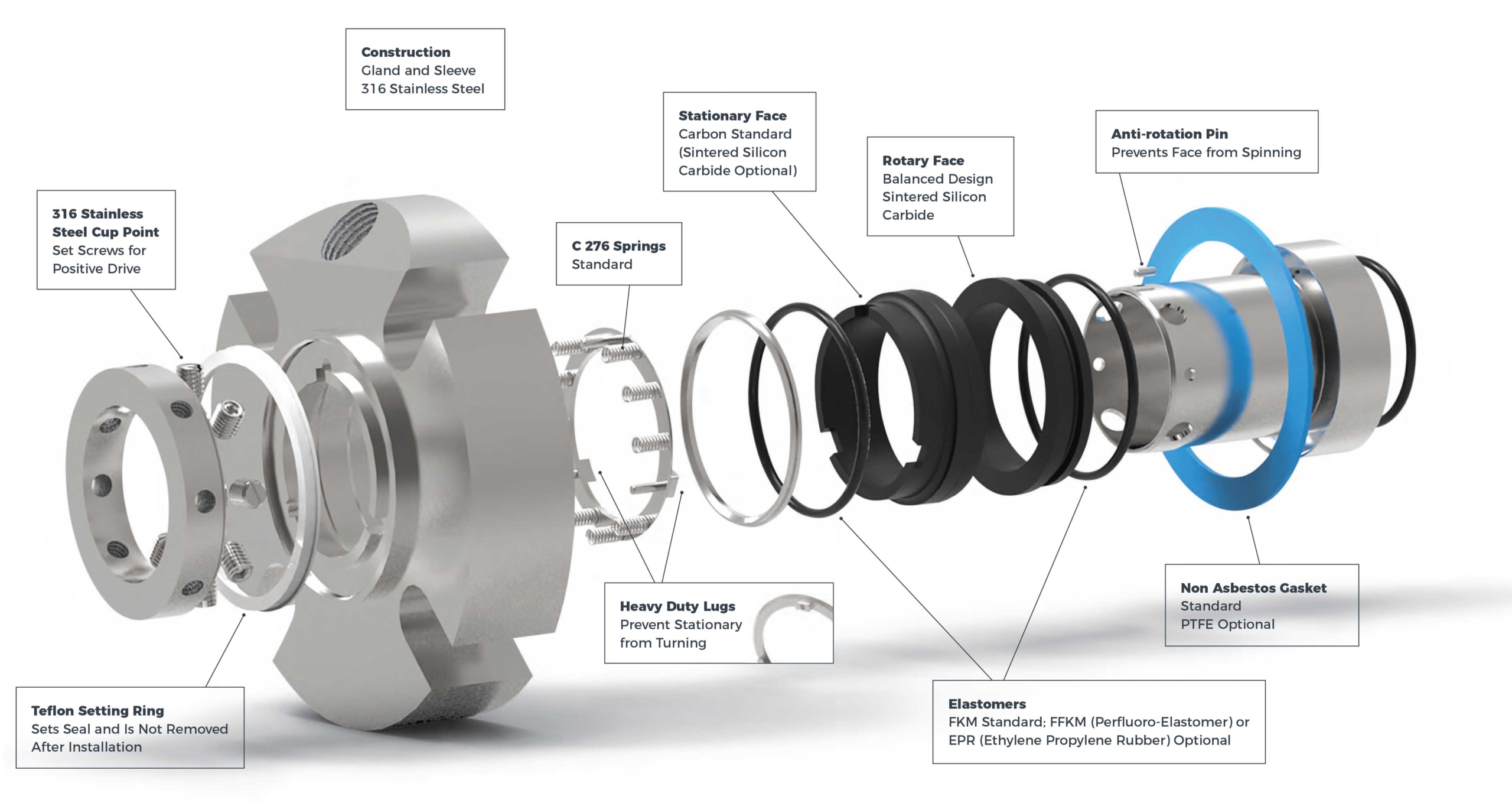

The O-ring for mechanical seals seals leak paths outside the primary seal faces. Statically, it ensures pressure tightness between components; dynamically, it can slide on the shaft or sleeve. That requires control of friction, lubrication, and surface roughness. In pusher designs, the O-ring for mechanical seals moves along dynamically. Choose an assembly and in-service lubrication that is compatible with the compound.

Secondary seals: static vs. dynamic (pusher/non-pusher)

In static positions, it’s about predictable compression, material stability, and burr-free grooves. In dynamic positions, you minimize stick-slip with the right roughness and proper fit so the O-ring for mechanical seals doesn’t “hang.” Consider tolerance stack-ups and thermal expansion between shaft and gland.

Self-energizing & compression (ISO 3601 groove dimensions)

Process pressure pushes the O-ring more firmly against the leak path (self-energizing). The groove geometry converts pressure into sealing force; over- or under-compression is penalized immediately. An O-ring for mechanical seals must have a low compression set. That way it retains recovery force. Check that your O-ring for mechanical seals matches ISO 3601 groove dimensions. This prevents excessive friction or too little preload.

Common failure modes: RGD, extrusion, compression set

RGD (rapid gas decompression) is recognized by blistering/cracking after a rapid pressure drop; extrusion by skiving into the clearance gap at high differential pressures; high compression set by permanent “flattening.” RGD damage occurs when an O-ring for mechanical seals is not AED-resistant. Limit extrusion with back-up rings and select compounds that retain their elastic properties within the temperature profile.

Material selection for oil & gas

The medium (hydrocarbons, H₂S/CO₂, amines, steam) and the temperature profile guide your material choice. The O-ring for mechanical seals must remain stable without swelling, hardening, or cracking, even under pressure fluctuations and cleaning regimes.

HNBR, FKM, AFLAS® & FFKM (temperature, sour service & extreme chemistry)

HNBR excels in sour service and mechanical robustness (reliable with H₂S-rich gases and cold starts). FKM (Viton®) performs well at higher temperatures and with solvents; at 150–200 °C, an O-ring for mechanical seals made of FKM often does better. AFLAS® (FEPM) is strong with amines, hot steam, and H₂S; for sour service, an O-ring of HNBR or AFLAS® is logical. FFKM offers maximum chemical and heat resistance; an O-ring for mechanical seals in FFKM pays off with extreme chemistry and heat. Base your choice each time on the worst-case operating window (start-ups, upset conditions, cleaning).

Design & installation

Clearance, alignment, and thermal expansion determine the actual load. An O-ring for mechanical seals benefits from consistent fit, correct roughness, and compatible assembly lubrication.

PTFE back-up ring: at high differential pressure/pressure

Differential pressure and clearance determine extrusion risk. At high differential pressure, an O-ring for mechanical seals should be used with back-up rings. Back-ups “take up” the clearance so the elastomer doesn’t extrude, even during pressure spikes. With PTFE back-ups, the O-ring for mechanical seals remains extrusion-free at high pressure.

Hardness (70–90 Shore A), roughness & lubrication

Harder (90 Shore A) helps against extrusion; softer conforms better to surface roughness. Match surface roughness to the dynamics: too rough causes wear, too smooth increases stick-slip. Choose a grease or oil that does not swell the compound. This way, the O-ring for mechanical seals retains its preload and service life.

Checklist for groove design according to ISO 3601

Verify dimensions, tolerances, and angles before ordering or assembly. Check that your O-ring for mechanical seals matches ISO 3601 groove dimensions. Consider chamfers and burr-free edges to avoid cutting damage; also ensure groove volume for thermal expansion.

Standards & selection: O-ring for mechanical seals

Standards provide a common language between engineering and procurement. The O-ring for mechanical seals must not only fit; it must be demonstrably suitable.

API 682/ISO 21049 (seals), implications for O-rings

These standards govern seal configurations, material selection, and testing. Translate that into your parts list: which O-ring for mechanical seals (compound/hardness), which back-ups, and which piping plan. Record the temperature/pressure/media windows in the datasheet.

NORSOK M-710 / ISO 23936-2 & NACE TM0297 (AED/RGD)

Request test reports for sour service and RGD. An AED-resistant O-ring with NORSOK/ISO qualification reduces the risk of unplanned shutdowns during depressurization. Also record how quickly you may reduce pressure during maintenance and start-up.

FAQ

No. Due to compression set, micro-damage and contamination, reuse is unreliable, especially in critical mechanical seals. Always replace with a new O-ring for mechanical seals from the same batch/compound.

Measure the inside diameter and cross-section with a precise caliper and choose one system: ISO 3601 (metric) or AS568 (inch). Do not mix them; grooves are designed specifically for one or the other.

Cool, dark, dry, in sealed original packaging; away from ozone/UV and solvent vapors. Apply FIFO, keep batch labels/CoC, and follow the supplier’s shelf life.

Don’t do this in this application. For mechanical seals, you want molded, endless rings; bonded splices are weak points, especially under pressure and temperature fluctuations.

Nederlands

Nederlands  Deutsch

Deutsch  Français

Français  Italiano

Italiano  Español

Español