Table of contents

- Materials: which material to use where in a coffee machine?

- Certifications and regulations

- Technical properties

- Maintenance of O-rings in coffee machines

- What to do if the coffee machine leaks?

- FAQ

Materials: which material to use where in a coffee machine?

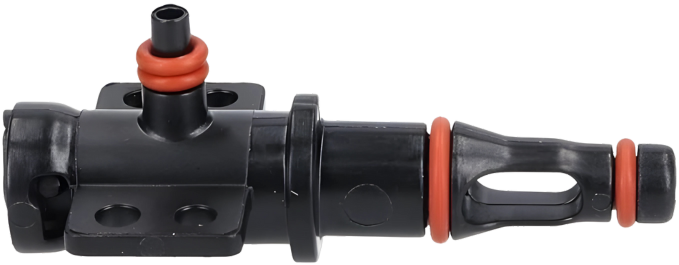

Not every O-ring is the same. The choice of material determines how well the ring withstands heat, steam, coffee oils, and cleaning agents.

- EPDM is by far the most commonly used material in coffee machines. It is excellently suited to hot water and steam, making it ideal for boiler and water circuits. The material is highly resistant to hydrolysis and temperature fluctuations.

- Silicone (VMQ) is widely used because of its flexibility and food safety. This material remains elastic under varying temperatures and is therefore suitable for static seals in the brew group or at connections. However, silicone wears more quickly in moving applications.

Technical properties

When choosing O-rings, both chemical and mechanical properties play a role. An important point is the temperature range. EPDM typically performs up to 120–150 °C and is therefore very suitable for hot water and steam. Silicone is often usable up to around 200 °C and retains its elasticity even with strongly fluctuating temperatures. In addition, compression set is an important factor: over time, O-rings can lose their resilience due to constant pressure and heat. This largely determines service life. Wear resistance also matters, especially in dynamic applications such as the brew group. Here the material must withstand friction and mechanical loading.

Maintenance of O-rings in coffee machines

For proper coffee machine maintenance, regular inspection of O-rings is essential. Inspect them at least annually and replace them at the first signs of wear such as small cracks, drying out, or deformation. With intensive use, such as in an office environment, more frequent replacement may be necessary.

Always use food-grade silicone grease to lightly lubricate O-rings during installation. This reduces wear, prevents drying, and ensures smooth assembly. Make sure the lubricant is suitable for potable-water and food-contact applications.

What to do if the coffee machine leaks?

A common complaint is that a coffee machine leaks. Often a worn O-ring is the culprit. Water droplets under the appliance, loss of pressure, or wet coffee pads can all be warning signs. By replacing the relevant O-ring and lubricating it correctly, the problem is usually solved quickly.

Even when people search for things like “Philips coffee machine leaks water” or “Jura coffee machine maintenance,” the solution often turns out to be universal: check and replace the sealing rings. Whether it’s a domestic fully automatic or a professional machine, the way the seals work remains the same.

FAQ

When the O-ring is dried out, cracked, or worn, it can no longer seal properly. Leakage or loss of pressure are clear signs.

Yes, usually. With the right size, a suitable replacement ring, and some food-grade silicone grease, this can be done easily at home.

Depending on use and maintenance, usually every 1–2 years. For professional or intensive use, more often.

Nederlands

Nederlands  Deutsch

Deutsch  Français

Français  Italiano

Italiano  Español

Español