Table of contents

- O-ring flange seal in the chemical industry

- Materials for O-ring flange seals: FKM, FFKM, EPDM and PTFE

- Installing an O-ring in a flange joint: step-by-step guide and tips

- O-ring maintenance and inspection checklist for flanges

- FAQ

O-ring flange seal in the chemical industry

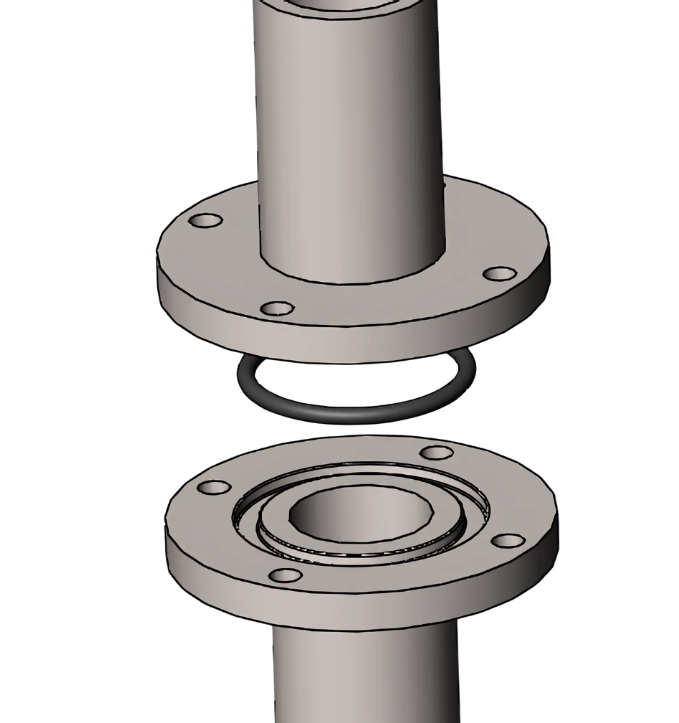

In piping systems, reactors, heat exchangers, pumps, and valves, an O-ring flange seal must remain reliable under thermal fluctuations and pressure cycles. Unlike flat gaskets, this solution requires less bolt load and compensates for micro-irregularities through elastic recovery. The result is a stable seal and lower leakage risks, even when the flange joint is opened more frequently for inspection or cleaning. If you opt early for an O-ring flange seal, you benefit from compact groove geometry and easy replacement during shutdowns. For processes with solvents, acids, or steam, the next step is to select a compound and hardness that match the medium, temperature, and pressure, so the O-ring flange seal retains its compression even after many cycles.

Materials for O-ring flange seals: FKM, FFKM, EPDM and PTFE

Material selection determines service life and safety. Start from the application and work back to the material: FKM (Viton) excels with fuels and many solvents and withstands higher temperatures; FFKM offers maximum chemical resistance for demanding media; EPDM performs well in water, steam and outdoor installations; PTFE is inert and suitable for fully static flanges. Use this as a quick shortlist for a durable O-ring flange seal.

Additionally, assess O-ring materials for hardness (Shore A), swelling, gas permeation, and thermal ageing. In corrosive processes, chemically resistant O-rings are the foundation; with highly aggressive media such as acids and alkalis, choose specifically chemically resistant O-rings for acids and alkalis, for example in FFKM or certain FKM compounds with proven resistance. Combine that material selection with supplier testing and part-to-part consistency so the O-ring flange seal performs predictably in batch and continuous processes.

Installing an O-ring in a flange joint: step-by-step guide and tips

Proper O-ring installation starts with clean, burr-free faces and a groove without damage. Apply a thin, compatible lubricant to prevent friction and twisting. Place the ring in the groove without stretching, close the flanges, and tighten the bolts in a criss-cross pattern and in stages. This basic approach makes the O-ring flange seal immediately leak-tight and reproducible.

Base the groove geometry on O-ring groove dimensions and compression per ISO 3601/AS568: too little squeeze causes micro-leakage, too much accelerates ageing. Use dimensionally stable back-up rings where needed to prevent extrusion. For higher pressures, a high-pressure flange seal with an O-ring and back-up ring works best to control clearance gaps and keep the O-ring flange seal stable under pressure fluctuations.

Also pay attention to “Surface roughness and tightening torque for a leak-tight O-ring flange.” A finish that is too rough or too smooth can undermine the seal; incorrect tightening torque leads to uneven loading. Therefore record tightening torques in maintenance procedures and train technicians to recognise twisting, so the O-ring flange seal remains predictably tight, even after interventions. In short: careful O-ring installation and validation prevents surprises at start-up.

O-ring maintenance and inspection checklist for flanges

Make O-ring maintenance a routine. During shutdowns, check for compression set (flattening), cracks, discoloration, and increased hardness. Replace proactively if in doubt, and record the medium, process conditions, and runtime; those data tell you when the O-ring flange seal is approaching its limits. Also watch the compatibility of cleaning agents with the chosen elastomer.

Many incidents are preventable on a recurring basis. Common mistakes with O-ring flange seals (and how to prevent them) often involve: the wrong compound for the medium, incorrect groove geometry, no back-up ring at high pressure, installing dry, or skipping crosswise tightening. Ensuring storage conditions (cool, dark, low-ozone) and FIFO use of spare parts helps keep the O-ring flange seal consistently reliable over the long term. By planning systematic O-ring maintenance, both leak reports and unplanned shutdowns decrease.

FAQ

Start with FKM and assess the fluid specifications; for the most severe media, FFKM is often the safest choice. For fully static flanges, PTFE can be a solution, provided you design the groove for it so that the O-ring flange seal retains its shape.

ISO 3601 and AS568 govern dimensions and tolerances; NORSOK M-710 focuses on performance in oil and gas environments, including explosive decompression. Following these references accelerates procurement and audit processes.

Nederlands

Nederlands  Deutsch

Deutsch  Français

Français  Italiano

Italiano  Español

Español