O-rings play a crucial role in general industry. They provide reliable sealing in a wide range of machines and installations, from hydraulic cylinders to pneumatic systems. Thanks to their versatility and long service life, O-rings prevent leaks, pressure loss, and malfunctions. On this page, you can learn how O-rings are applied in industrial environments and which materials are best suited for specific conditions.

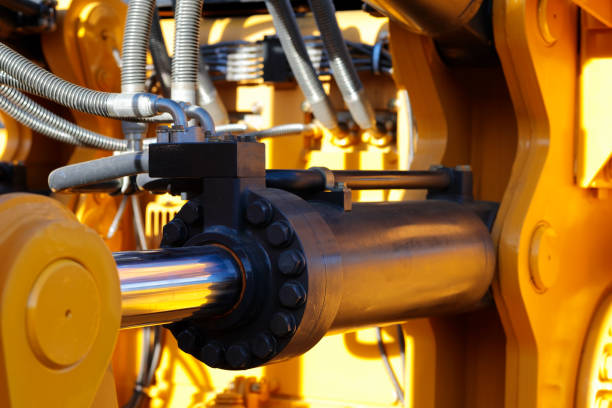

A key application area for O-rings is hydraulics. In hydraulic systems, fluid under high pressure is used to transmit force. Examples include cylinders that move heavy loads or valves that regulate oil pressure. In all these components, O-rings ensure leak-free operation. Even a small leak can cause pressure loss and costly production downtime. For this reason, FKM (Viton) O-rings are often used in hydraulics: they are resistant to oil, fuel, and high temperatures.

O-rings are also essential in pneumatics. Here, the medium is not fluid but compressed air or gas. Applications include air cylinders, valves, and compressors. Without proper sealing, energy is lost, reducing system efficiency. In such applications, EPDM O-rings perform excellently, as they are highly resistant to dry air, ozone, and aging. For higher temperature applications or when flexibility is required, silicone O-rings are often selected.

The use of O-rings in general industry is broad and diverse, and they can be found almost everywhere. In mechanical engineering, they are standard in couplings and seals. In maintenance and repair, O-rings are often the first replacement part in case of a failure. The chemical industry requires special materials that resist acids and solvents, while the food industry imposes strict hygiene and safety requirements.

What all these sectors have in common is that O-rings contribute to continuity and safety. A good seal ensures that production lines keep running and that processes remain reliable. For each of these applications, there is a suitable O-ring available, ranging from standard rubber to high-performance materials such as PTFE or FKM.

The versatility of O-rings is mainly due to the wide choice of materials. Each material has unique properties and is suitable for specific conditions:

NBR O-ring: the standard choice in industry. Rubber O-rings are versatile, cost-effective, and ideal for general applications.

EPDM O-ring: resistant to hot water, steam, and ozone. Widely used in pneumatic systems and the food industry.

Silicone O-ring: highly flexible and resistant to a wide temperature range. Suitable for applications where food safety and elasticity are important.

PTFE O-ring: excellent resistance to aggressive chemicals. Commonly used in the chemical industry or in processes where standard rubber falls short.

FKM (Viton®) O-ring: performs well at high temperatures and in contact with oil or fuel. Essential in hydraulic systems.

By making the right choice, you can prevent malfunctions and extend the life of your machines. When in doubt, it is advisable to consult a specialist, as conditions in industry can vary widely.