Table of contents

- Where are O-rings located in the control block of a dental unit?

- O-ring material selection for dental control blocks

- Step-by-step: replace the O-ring in the valve block

- Common leaks and symptoms with O-rings in the air-water block

Where are O-rings located in the control block of a dental unit?

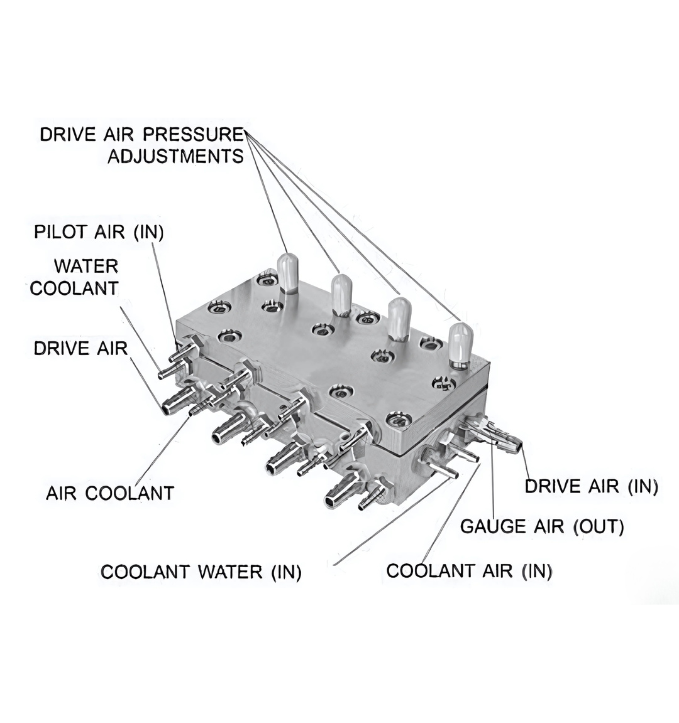

Under each solenoid lies a static seal that closes the valve foot against the aluminum block. As soon as this ring hardens or gets a burr in the contact surface, you hear a soft hiss or notice traces of moisture. O-rings in the control block of a dental unit provide pressure-tight silence here; replacement is only durable if you make the seat clean and scratch-free and use the correct torque.

Inside the valve, small rings dynamically seal the spool or plunger. With wear, air or water continues to blow through, causing instruments to drip or run at half power. In practice, a complete overhaul kit is more reliable than a single ring, especially with compact cartridge valves such as those often found at Dentsply Sirona. That brings the valve’s shutoff and response time back to factory level.

Service plugs also use face-seated seals to separate individual channels in the block. A damaged ring lets pressure leak away or causes cross-influence, whereby a non-selected instrument briefly joins in. O-rings in the control block of a dental unit are the invisible workhorses here: a clean groove, a new ring, and the right torque solve most problems without further adjustments.

Many units work with a modular manifold. Between those sections lie flat rings that separate parallel air and water runs. If they get crushed or shifted, performance differences arise between seemingly identical instrument lines. Tighten in a cross pattern, remove micro-burrs, and check flatness; that keeps the air-water block stable across the full width.

Push-in couplings clamp the hose’s outside diameter and seal with an internal O-ring. Wear or chemical attack produces micro-leakage: a restless spray, rpm fluctuations, and faster pressure loss. Replace the internal ring, cut the hose end square, and check concentricity. O-rings in the control block of a dental unit perform best when the cut face is truly square, regardless of brand or fitting size.

Finally, backflow prevention and anti-retraction rely on small O-rings that close as soon as pressure falls away. When those seals become fatigued, rinse water can flow back toward lines and handpieces. A new ring and a spotless seat prevent recurrence and help keep microbial load low.

O-ring material selection for dental control blocks

Material determines how long a seal remains elastic and chemically stable. In water and steam circuits, O-rings in the control block of a dental unit often perform best with EPDM: resilient after thermal cycles and compatible with many disinfectants. Avoid petroleum-based grease with EPDM, as it causes swelling and loss of strength.

NBR (nitrile) is a solid all-rounder for compressed air and mild oils. It is affordable, wear-resistant, and easy to obtain, but it ages faster at high temperature or under aggressive oxidants. Therefore, use it mainly in air channels, and choose EPDM in water runs. This way, O-rings in the control block of a dental unit get, per channel, the compound that matches the medium and process.

FKM (fluoroelastomer) excels under higher chemical and thermal load. Not every FKM compound is steam-resistant; always check the parts list or service instructions before using FKM in hot water or steam circuits. Where steam compatibility is confirmed, FKM delivers excellent dimensional stability and long service life, including in compact manifolds such as those regularly used by KaVo.

Silicone (VMQ) remains exceptionally supple and is useful where low closing force or frequent disassembly matters, for example in certain plug seals. It is less wear-resistant than EPDM or NBR and therefore less suitable for dynamic positions. Choose silicone selectively and for a clear reason, not out of habit.

Besides the compound, hardness and sizing carry a lot of weight. In valve blocks, Shore 60–70 A often provides a good balance between sealing pressure and dimensional stability. Measure groove diameter and cross-section, or order by part number; do not rely on the old ring, as it is usually flattened or stretched.

Step-by-step: replace the O-ring in the valve block

Start with safety: power off, close air and water, and depressurize the system. Photograph the initial situation, label hoses and connectors, and work cleanly with lint-free cloths and a plastic pick. In the control block of a dental unit, replace O-rings preferably as a set when multiple seals jointly fulfill one function; this prevents a worn mating ring from quickly compensating for the new one.

Disassemble the valve or plug without damaging grooves, clean the seat, and inspect for scratches and burrs. Assess the old ring: flat sides (compression set), hairline cracks, and tackiness reveal a lot about end-of-life or unfavorable chemistry. Install a new ring of the exact size and material, lay it relaxed in the groove, and apply at most an ultra-thin film of compatible grease. Tighten to the specified torque and test under operating pressure: actuate the channel, listen for leaks, and observe rotational speed and spray behavior. With this approach, practices with Planmeca units often find that start-stop behavior becomes immediately crisper.

Common leaks and symptoms with O-rings in the air-water block

A continuous hiss at rest usually points to a static leak beneath a solenoid foot or plug. After replacement and seat refacing, the silence should return. If a spray or airflow keeps running on, the internal spool rings no longer seal properly; an overhaul kit restores the response, something that’s also clearly noticeable in KaVo installations. Fluctuating power or an irregular spray pattern often stems from microleakage in push-in fittings or from a fatigued needle-valve seal. Renew the internal ring, cut the hose end square, and readjust the flow.

If system pressure drops quickly after shutdown, think of check-valve and anti-retraction seals. Small leaks have a big impact on start-up behavior for the next patient. After intensive cleaning or thermal load, rings with a high compression set may leak briefly; switching to EPDM in water runs or a steam-suitable FKM variant often solves this structurally. Those who follow these basics will also find, with compact cartridge solutions from Dentsply Sirona, that stability is not a coincidence but the result of the right compound in the right place.

FAQ

Petroleum- or solvent-rich sprays and certain strong oxidants can cause swelling or hardening, especially in NBR. Always check your compound’s compatibility chart and rinse with water where possible.

That depends on cycles, temperature, and chemistry, but many rings last 1–3 years with proper maintenance. Schedule inspection during periodic service, and replace preventively in case of compression set, hairline cracks, or tackiness.

Twisting during installation, too much or unsuitable grease, and grooves with burrs are classics. A “nearly right” size crops up too: too thick skives off, too thin leaks, always choose the exact size and compound.

Nederlands

Nederlands  Deutsch

Deutsch  Français

Français  Italiano

Italiano  Español

Español