Table of contents: O-rings for valves

- General: O-rings for valves (locations, functions and application examples)

- Potable-water O-rings: material selection (EPDM vs. FKM/FFKM) and WRAS/NSF 61

- Design per ISO 3601: groove dimensions, compression and PTFE back-up rings

- Installation and maintenance: assembly, lubrication and leak prevention

- FAQ

General: O-rings for valves (locations, functions and application examples)

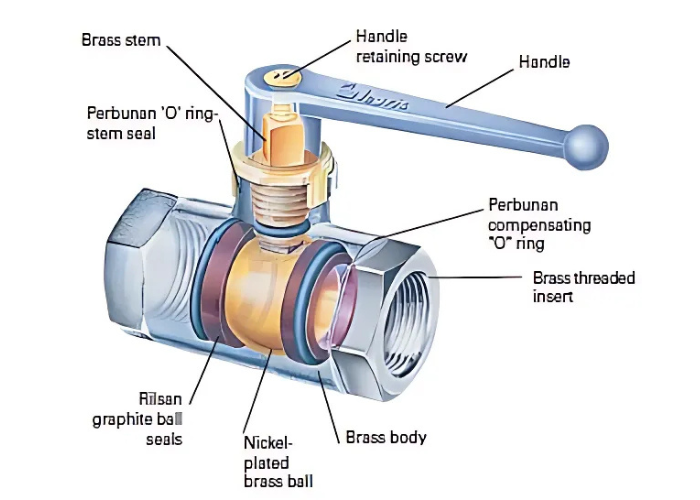

Anyone working in water and wastewater treatment encounters O-rings for valves in fixed locations: around the stem (stem seal), between body and bonnet/cover (bonnet/cover seal), at service covers, and at the actuator interface. In butterfly valves, O-rings are often located above and below the shaft to guarantee a dry passage; in gate valves you’ll see them on the bonnet, allowing you to seal without a flat gasket. Ball and plug valves use O-rings for the stem seal and sometimes as a “seat-energizer”: an O-ring that preloads the seat so the valve seals even at low pressure. In check valves, O-rings serve the service cover so inspection and maintenance can be carried out quickly. O-rings for valves in this industry are therefore primarily about reliable static seals, with slow dynamic movement during operation. That may seem simple, but water hammer, pH fluctuations, and oxidative disinfection impose a harsher lifetime load than in many other sectors. That’s why we address O-rings for valves below in terms of medium, design, and maintenance.

Potable-water O-rings: material selection (EPDM vs. FKM/FFKM) and WRAS/NSF 61

The basic rule for drinking water is clear: choose compounds that meet the applicable scheme in terms of hygiene, migration, and taste/odour. In the Netherlands and the United Kingdom you often encounter KIWA and WRAS/BS 6920; in North America, NSF/ANSI/CAN 61 is common. For drinking-water O-rings, EPDM is usually the first choice because it performs excellently in water and resists ozone, chlorine, and chloramines at typical concentrations and temperatures. EPDM O-rings are also widely available as WRAS-certified O-rings and as NSF 61 O-rings, including low-compression-set variants. O-rings for valves in sodium hypochlorite or chlorine-dioxide dosing require extra attention: compatibility depends on pH, temperature, and concentration. In those situations, a high-grade EPDM compound or, where chemistry and temperature demand it, an inert solution with a PTFE insert or FFKM is a sensible route. FKM (Viton®) can be useful with oil and fuel exposure in pump environments, but is less suitable for hot water/steam and strong oxidizers; use it selectively.

For wastewater and sludge, where H₂S and organic components come into play, EPDM often works well, but check process conditions and consider FKM or FFKM at higher temperatures or with solvents. Specifically for operators undergoing audits: explicitly request WRAS-certified O-rings and verify that the EPDM O-rings combine low compression set with the correct Shore hardness. Under higher oxidative load, it pays to choose chlorine-resistant O-rings or to combine valve O-rings with PTFE inserts when temperature and concentration rise. In this way, EPDM O-rings and drinking-water O-rings for valves become a link between compliance and reliability: you select not only on chemistry, but also on the required certificates and on service life within your cleaning, rinsing, and disinfection cycle.

Design per ISO 3601: groove dimensions, compression, and PTFE back-up rings

A good material choice stands or falls with the correct groove design. ISO 3601-1 defines the standard dimensions for O-rings for valves; ISO 3601-2 provides guidelines for groove dimensions. In practice, you control three parameters: squeeze (axial or radial compression), gland fill (what percentage of the groove the O-ring fills), and stretch/diametral clearance.

For water applications, 70 Shore A is often a good starting point, with a squeeze that ensures leak tightness without overloading the O-ring. At higher pressures or with an enlarged “gap” (the clearance between metal parts), the risk of extrusion increases, the phenomenon in which the O-ring is forced into the gap and damaged. This is where PTFE back-up rings come into play. These back-up rings, described in ISO 3601-4, support the O-ring on one or both sides, limit the effective gap, and absorb pressure spikes. In piping systems with water hammer or frequent actuations, a 90 Shore A O-ring with PTFE back-up rings is often the safest choice. This increases the operational reliability of O-rings for valves in networks with fluctuating pressure.

Bear in mind that O-rings for valves also influence operating torque: excessive friction in the stem seal can cause stick-slip. With a potable-water-approved lubricant applied sparingly, you reduce that friction without endangering the seal. O-rings for valves sized according to ISO 3601, with the right hardness and back-up configuration, withstand pressure cycles better and maintain their shape, making maintenance intervals more predictable.

Installation and maintenance: assembly, lubrication, and leak prevention

Most leaks we see in the field have less to do with “wrong material” and more with installation errors. Start with a clean, burr-free groove; even small burrs or sharp edges will cut into the elastomer during installation. Use an installation aid or chamfers so you don’t twist the O-ring when sliding it over threads or sharp transitions. Apply a sparing layer of drinking-water-approved lubricant; this prevents friction and micro-cracks during assembly. For the valve stem seal, use a thin, potable-approved film of assembly grease; for dosing lines with oxidizers, switching to chlorine-resistant O-rings can prevent unnecessary failures. O-rings for valves benefit from consistent tightening torques on covers, bonnet seals, and service covers: uneven compression creates local leak paths.

After commissioning, a brief visual check is useful, especially in systems with NaOCl or ClO₂: oxidative media accelerate ageing when concentration or temperature turns out higher than expected. If you see compression set (a permanently “flattened” profile), reduce the gland fill or choose a compound with better set values. If you see signs of extrusion or sheared lips, reduce the clearance gap or fit PTFE back-up rings. O-rings for valves are relatively inexpensive; therefore, on critical assets plan preventive replacement based on operating hours or actuations, not just calendar years. Record batch numbers, compound codes, and certificates so you can reinstall exactly the same quality at the next shutdown. With this discipline, valve O-rings perform predictably, failure risk drops, and your drinking-water or effluent quality remains assured.

FAQ

EPDM is generally the first choice. Make sure you select a drinking-water grade with WRAS or NSF 61 certification, and that the valve O-rings also match your groove in terms of hardness and compression set. For critical points under WRAS/BS 6920, WRAS-certified O-rings are often required.

If you work with higher pressure, have a larger gap, or expect pressure spikes/water hammer. PTFE back-ups limit extrusion and extend service life. For many butterfly and gate valves in networks, this is a sensible standard, especially for Butterfly Valve O-rings and Gate Valve O-rings that face pressure peaks.

Not necessarily. FKM performs well with oils/fuels but is less suitable for hot water/steam and some oxidizers. For chlorine or chloramine dosing, a suitable EPDM grade or, under severe conditions, an inert solution (e.g., PTFE insert or FFKM) is often better. In dosing lines with higher oxidative load, chlorine-resistant O-rings with validated test data can provide a solution.

The stem seal contributes to friction. Choose a suitable compound, size the groove according to ISO 3601, and use a drinking-water-approved lubricant to prevent stick-slip and keep the torque stable. This keeps valve O-rings in top condition, even with frequent actuations.

That depends on switching frequency, medium, and temperature. In critical lines (disinfection, inlet), a preventive replacement during scheduled shutdowns is advisable. Inspect for compression set, cracks, and signs of extrusion; replace if in doubt. O-rings for valves are inexpensive compared to the cost of unplanned downtime.

Keep batch and compound codes, certificates (WRAS/KIWA/NSF 61), any test reports, and a note of groove dimensions and tightening torques. This allows you to demonstrate that O-rings for valves meet the requirements, perform reproducibly, and that the O-rings for valves are traceable.

Nederlands

Nederlands  Deutsch

Deutsch  Français

Français  Italiano

Italiano  Español

Español