Table of contents

- O-rings for pneumatic cylinders: applications

- O-rings for pneumatic cylinders: material selection

- O-rings for pneumatic cylinders: maintenance & service life

- O-rings for pneumatic cylinders: hygiene & certification

- FAQ

O-rings for pneumatic cylinders: applications

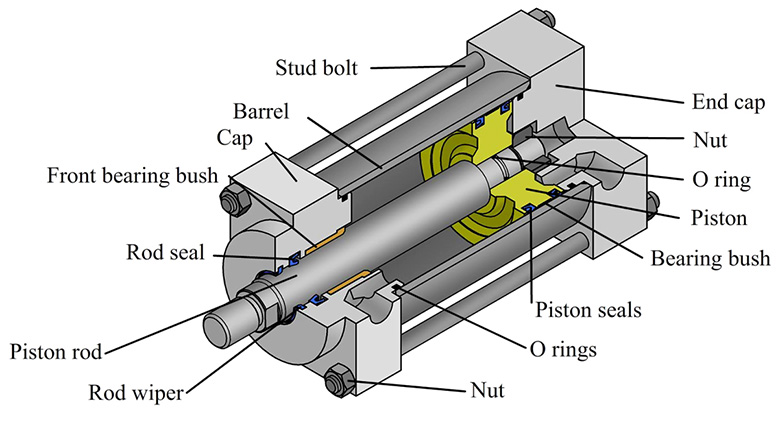

In the piston, O-rings act as dynamic seals that separate the pressure chambers and make the stroke leak-free. This is the most heavily loaded position: the seal moves, sees pressure fluctuations, and determines repeatability. Here, friction and the lubricating film make the difference between a tight cycle time and stick-slip that disrupts your entire takt time.

Between the cylinder tube and end cap, and at port connections, O-rings for pneumatic cylinders prevent bypass and unwanted ingress or egress of fluids. Think of static seals at end caps, plugs, and manifold interfaces. In food environments, it is especially important that the groove is designed without dead corners and is easy to rinse; that way, residues of product and cleaning agents do not remain and the microbial risk stays low.

O-rings for pneumatic cylinders: material selection

For CIP/SIP, choose EPDM O-rings for pneumatic cylinders with high steam resistance. EPDM retains elasticity under heat and water vapor, generally tolerates alkaline and acidic cleaners well, and in this context delivers stable compression over time. As a result, preload remains uniform and sealing integrity reliable, even when the line is washed or sterilized daily.

Where greases, oils, or compressed-air oil play a role, FKM O-rings are often the better choice. FKM excels in resistance to oily media and many chemicals, while also offering a broad temperature range. If you primarily need chemical inertness and low friction, a PTFE solution can make sense: for example, a PTFE-encapsulated ring or a PTFE seal with an elastic energizer. Such solutions limit tackiness, keep friction low, and minimize the chance of material transfer to the product.

Material selection is more than a “compatible or not” checklist. Also consider hardness, compression set, and behavior under thermal cycling. A compound with low compression set prevents the seal from becoming “tired” after many hours under clamping force. And watch grease compatibility: some elastomers swell when in contact with certain lubricants. By factoring these aspects in, you turn the O-rings for pneumatic cylinders into reproducible components in your process rather than variables.

O-rings for pneumatic cylinders: maintenance & service life

Plan maintenance on data, not on gut feel: replace the O-rings for pneumatic cylinders preventively based on cycles, actuations, and recorded CIP hours. By setting machine-type-specific thresholds, you shift from reactive to predictive maintenance. That shortens downtime and prevents a seemingly small leak from gradually causing compressed-air losses and quality issues.

During inspections, it’s important to look beyond “leak yes/no.” Check the O-rings for flat spots (flat areas from prolonged compression), for cracks after steam cycles, and for swelling due to unfavorable media. Also assess the groove: burrs or sharp transitions can nick the seal during installation. A small investment in chamfering and polishing quickly pays off in longer service life and fewer unexpected failures.

Lubrication deserves separate attention. A thin, food-grade lubricating film reduces friction and damps stick-slip, but must not undermine cleanability. Consider wipers or double scrapers to keep water and dirt off the rod. During cleaning, it’s wise to extend the rod; this limits water ingress along the wiper and protects the O-rings for pneumatic cylinders against moisture ingress. Finally, work with traceable batches and record replacement times; this makes correlation with failures or recipe changes possible.

O-rings for pneumatic cylinders: hygiene & certification

Documentation is just as important as the material itself: use O-rings for pneumatic cylinders with up-to-date FDA and EC 1935/2004 statements, and, where relevant, secure GMP (EG 2023/2006), USP Class VI, or 3-A. Ask for compound codes and batch certificates so that audit trails are complete. In aseptic processes, it pays to include validation data in your change-control; this prevents surprises during requalification.

Choose O-rings for pneumatic cylinders from compounds with FDA and EC 1935/2004 conformity (such as EPDM, FKM, or PTFE solutions available at O-ring-stocks). Combine this with hygienic groove design: radii instead of sharp internal corners, good drainage, and a surface that can be rinsed. The right hardness (often 70 Shore A) balances sealing force with cleanability and limits the risk of cold flow in plastic housings. At higher differential pressure or larger clearances, prevent extrusion with PTFE back-up rings. This way, sealing becomes not only a technical choice but also a food-safe one.

EPDM O-ring for CIP/SIP and steam; FKM O-ring for contact with oil/grease; PTFE O-ring (or PTFE seal with energizer) for chemical inertness and low friction.

Use compounds with FDA and EC 1935/2004 declaration; ensure GMP (EG 2023/2006), and where appropriate USP Class VI plus batch/lot certificates for traceability.

Choose a compound with low compression set and approx. 70 Shore A hardness, apply hygienic groove design and use a thin food-grade lubricating film; use wipers/double scrapers against water and dirt.

Set intervals in a data-driven way based on cycles/actuations and CIP hours; inspect for flat spots, swelling, and cracks, and replace preventively to avoid unexpected downtime.

Nederlands

Nederlands  Deutsch

Deutsch  Français

Français  Italiano

Italiano  Español

Español