FEP Encapsulated O-Rings are high-performance sealing solutions combining an elastomer core with a chemical-resistant FEP coating. Their strong resistance to chemicals and temperature makes them ideal for demanding environments like the pharmaceutical, chemical and food industries. With FDA approval and a smooth surface, these seals ensure safe and hygienic performance where reliability is crucial. Want to learn more? Explore the full details below.

FEP-encapsulated silicone O-rings combine the chemical resistance of FEP with the flexibility of silicone, offering reliable sealing from -55 °C to +200 °C. Their unique feature is the improved flexibility over PTFE while maintaining excellent chemical resistance, making them ideal for static seals in aggressive chemical environments.

FEP-encapsulated FKM O-rings offer strong chemical resistance with a temperature range of -15 °C to +200 °C, combining the durability of FKM with the protective FEP jacket. Their unique advantage is greater flexibility than PTFE while maintaining excellent resistance to aggressive media, making them ideal for static sealing in harsh chemical environments.

FEP Encapsulated O-Rings are high-quality sealing components that combine an elastomer core with a chemically resistant FEP coating. This unique construction provides exceptional resistance to aggressive chemicals, high temperatures and low friction. FEP Encapsulated O-Rings are ideal for use in the chemical, pharmaceutical and food processing industries. Thanks to FDA approval, they are safe for use in hygienic environments. They also offer long service life and high reliability, even under demanding conditions. As a result, they are often used where standard O-rings fall short in terms of chemical compatibility or thermal stability. In critical situations, the FEP O-Ring is the perfect option.

FEP Encapsulated O-Rings are advanced sealing solutions composed of an elastomer core such as Viton or silicone, covered by a seamless fep coating. This combination delivers excellent chemical resistance along with temperature tolerance, making them suitable for harsh environments. The FEP sheath, made of a thin layer of fluorinated ethylene propylene, protects the inner core from aggressive substances and prevents wear. The elastomer core ensures consistent sealing performance. Encapsulated o rings are commonly used in the chemical, pharmaceutical and food industries. Their low friction coefficient and FDA approval make them ideal for critical applications where durability and hygiene are essential.

FEP Encapsulated O-Rings typically feature a core made from Viton or silicone, encapsulated in a durable FEP coating. The core provides elasticity and sealing pressure, while the FEP outer layer protects the ring from corrosive chemicals and extreme temperatures. These fep o ring designs combine the chemical resistance of PTFE with the flexibility of traditional elastomers. This makes them widely applicable in chemical, pharmaceutical and food-related settings. Their smart construction delivers a long-lasting and reliable seal.

FEP Encapsulated O-Rings offer a strong sealing solution through the combination of a resilient inner structure and a chemically resistant outer layer. The core, made of Viton or silicone, provides the required flexibility and sealing force. The FEP encapsulation shields the o-ring from corrosive chemicals, high temperatures and mechanical wear. Because of these features, fep teflon based o-rings are used extensively in industries where durability and chemical resistance are key, such as pharmaceuticals and chemical processing.

The FEP Encapsulated O-Ring offers a wide range of advantages over standard O-rings and traditional PTFE rings. Their fep coating makes them highly resistant to aggressive chemicals, solvents and extreme temperatures. This makes them a perfect choice for demanding applications in the chemical and pharmaceutical industries. Unlike rigid PTFE rings, FEP O-Rings retain flexibility and sealing force, thanks to their elastomer core made of Viton or silicone. Their low-friction surface helps reduce wear and makes them easier to install. FDA-approved and built for hygienic use, these o-rings are ideal for food processing environments. Their long service life and dependable performance make FEP Encapsulated O-Rings the preferred solution in critical applications.

FEP Encapsulated O-Rings provide excellent protection against aggressive chemicals such as acids, bases and solvents. The fep coating ensures that the o-ring remains intact even in highly corrosive environments. This makes them an ideal choice for use in chemical and pharmaceutical industries. Additionally, FEP Encapsulated O-Rings maintain their sealing capabilities at temperatures ranging from -200°C to +205°C. They are perfectly suited for both cryogenic applications and high-temperature processes. Their unique combination of chemical resistance and thermal stability results in a long-lasting and reliable seal for critical environments.

FEP O-Rings have an ultra-smooth surface, resulting in a low coefficient of friction. This reduces resistance and wear, making them ideal for applications that require smooth and efficient sealing.

Thanks to the protective outer shell of fep teflon, these o-rings retain their shape and function even after long-term exposure to harsh chemicals and elevated temperatures. This durability allows them to outperform standard o-rings in demanding industrial environments.

FEP Encapsulated O-Rings are FDA-approved, making them highly suitable for applications in food processing, pharmaceuticals and medical equipment. Their chemical inertness ensures that they do not react with food products or pharmaceutical substances, providing a safe and hygienic seal. The smooth, non-porous surface of FEP Encapsulated O-Rings prevents the buildup of bacteria and contaminants, making them easy to clean. This makes them the ideal choice for environments where hygiene and safety are essential.

FEP Encapsulated O-Rings are used across a wide range of industries where extreme chemical resistance and reliable sealing performance are required. Their unique combination of an elastomer core and fluorinated ethylene propylene shell makes them particularly effective in chemical and petrochemical environments, where conventional o-rings may degrade. Because they are FDA-approved, they are also widely used in the food and pharmaceutical industries. Their low contamination risk and excellent sealing properties also make them suitable for use in laboratories, medical devices and the semiconductor industry. Their broad temperature range and long lifespan make FEP O-Rings a trusted sealing solution in high-demand situations.

FEP Encapsulated O-Rings are a smart solution for the chemical and petrochemical industry. They maintain performance even when exposed to acids, bases and solvents. Where other o-rings may fail due to chemical degradation, these encapsulated o rings remain stable and secure. They are commonly found in systems that handle corrosive substances, such as storage tanks, pipeline systems and chemical reactors. Even in highly demanding scenarios, their design allows them to perform reliably and consistently.

FEP Encapsulated O-Rings are FDA approved and well suited for use in food production and pharmaceutical manufacturing. Their chemical inertness and non-porous surface provide a clean and safe sealing solution. They withstand aggressive cleaning agents and elevated temperatures, maintaining sealing performance in hygiene-sensitive environments. FEP Encapsulated O-Rings help prevent contamination and meet strict regulatory standards, making them suitable wherever hygiene and reliability are required.

FEP Encapsulated O-Rings perform exceptionally well in medical equipment and laboratory settings thanks to their chemical inertness and low contamination risk. Their non-porous surface and high resistance to aggressive chemicals ensure they remain intact, even during sterilization and disinfection processes. These properties make FEP Encapsulated O-Rings the right choice for environments where hygiene and safety are critical. They are commonly used in lab instruments, pharmaceutical production and medical devices as a reliable long-term sealing solution without the risk of contamination or material breakdown.

FEP Encapsulated O-Rings are widely used in the semiconductor and aerospace sectors due to their high tolerance to extreme temperatures and corrosive substances. In these high-tech environments, maintaining a stable seal is essential.Thanks to their chemical inertness and low permeation, FEP Encapsulated O-Rings remain effective for long periods in vacuum systems and precision equipment. This makes them a logical choice in industries where precision, long service life and consistent performance are non-negotiable.

Despite their many benefits, FEP Encapsulated O-Rings do come with certain limitations. One drawback is that they are less flexible than standard elastomer o-rings, making them more prone to cracking under high mechanical stress. As a result, they are not ideal for dynamic systems with constant movement or stretching. They are also more expensive than standard sealing solutions due to the additional manufacturing processes and the use of fep teflon. In addition, the thin FEP shell can delaminate under high-pressure or steam exposure. It is essential to carefully assess the application to ensure proper o-ring selection and avoid future failures.

FEP Encapsulated O-Rings are less elastic than traditional o-rings. The FEP outer layer limits their stretchability, making them more susceptible to breaking under high strain or pressure. Under heavy mechanical loads or in dynamic applications, these o-rings may crack or lose their sealing performance. They are better suited for static installations where movement is minimal.

FEP Encapsulated O-Rings are not recommended for moving or reciprocating systems due to their limited deformability and wear resistance. The rigid fep coating reduces flexibility, leading to damage under repeated motion or mechanical stress.

For this reason, the FEP O-Ring is mainly used in static sealing scenarios. In environments with continuous friction or fluctuating pressure, they may lose effectiveness. In such cases, alternative sealing materials are more appropriate.

FEP Encapsulated O-Rings are more expensive than standard elastomer o-rings. This is due to their complex manufacturing process and premium materials. The combination of a fep o ring shell and elastomer core provides excellent resistance, but also leads to higher production costs. While they offer longer lifespan and better performance, the higher initial investment may be a consideration in large-scale use. It's important to weigh the benefits against the cost to determine whether they are the right choice for your specific application.

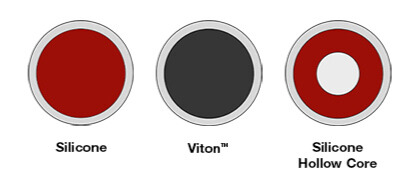

When selecting FEP Encapsulated O-Rings, it's important to choose between a Viton or silicone core depending on the application's requirements. FEP Viton o-rings offer strong chemical resistance and are suitable for oils, fuels and temperatures up to +205°C. They are commonly used in chemical, petrochemical and industrial settings. FEP Silicone o-rings, on the other hand, are more flexible and better suited for low-temperature conditions down to -60°C. They are ideal for cryogenic applications or environments where elasticity is important. Both versions combine the chemical resistance of fluorinated ethylene propylene with the functional advantages of the inner core. Depending on the environment, FEP O-Ring with Viton or silicone provide efficient and durable sealing performance.

FEP Encapsulated O-Rings with a Viton core are designed to withstand harsh substances such as oils, fuels and solvents. The Viton core and FEP shell work together to maintain sealing strength even in demanding conditions. These o-rings are rated for temperatures up to +205°C, making them suitable for various chemical and petrochemical applications. FEP encapsulated viton o rings are specifically designed for use in environments requiring both thermal and chemical resistance.

FEP Encapsulated O-Rings with a silicone core are more flexible and better suited for low temperatures down to -60°C. This makes them ideal for cryogenic environments where flexibility and performance under cold conditions are essential. The FEP coating ensures chemical resistance and wear protection, while the silicone core provides a soft and effective seal. They are commonly used in laboratories, medical environments and pharmaceutical production due to their excellent resistance to aggressive chemicals and cleaning processes.

FEP Encapsulated O-Rings are the ideal sealing solution for applications requiring chemical protection, temperature resistance and durability. Their smart design combines a flexible inner core with a completely enclosed FEP shell made from a thin layer of PTFE, providing reliable sealing even under heavy stress. They offer resistance to chemicals, oils and solvents while maintaining flexibility. FDA-approved and compliant with USP Class VI, they are safe for use in the pharmaceutical, food and medical industries, as well as in chemical and petrochemical systems. Although more expensive than standard o-rings, the o ring fep compensate with long service life and consistent performance. In critical sealing environments where reliability and chemical compatibility are essential, FEP Encapsulated O-Rings offer a durable and dependable solution.

.webp)