In our O-Ring Laboratory we perform many tests for our customers.

On the right side you'll see the most common tests we perform.

Please contact us for further information.

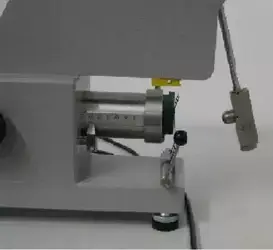

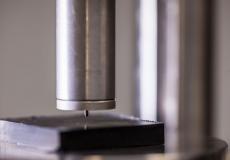

Hardness and density are quickly and conveniently determined, making them ideal for incoming goods inspection and testing.

The hardness test is probably the most applied and most common test method in the elastomer industry.

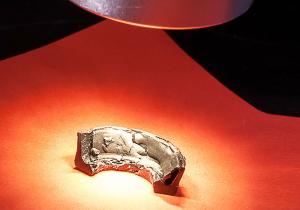

This test assesses the degree to which a seal or material loses its ability to recover its original shape after undergoing specific thermal stress conditions.

This test indicates how much a seal or a material loses its recovery behaviour after predefined thermal stress.

The practical benefit of this test entails ascertaining the degree of cross linking of finished parts where a compression set test is not applicable.

This test is not only about physical material properties, it can reveal a lot more.

We conduct durability tests in oil, fuels, coolants, refrigerants, superheated steam and many more media.

The thermal resistance of an elastomer ranks among its most important characteristics. However, there are different possibilities to check it.

Many elastomers may become cracked even under normal environmental ozone concentrations.

Thermogravimetric analysis (TGA) is one of the most commonly utilized analytical tests for elastomer materials.

The dimensional stability of seals is intimately connected to their ease of mounting and proper operation.

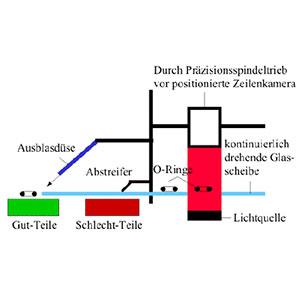

If the sealing measurements are inaccurate and an urgent remedy is required, then the only solution is to re-sort the components.

Visual inspection plays a crucial role as a safeguard due to the challenging processability.

During this test, the continuous measurement tracks the variation in sealing force over time, considering the impact of temperature, medium, and testing duration.

This test is crucial for dynamic seals, and significant variations can exist within a material category.

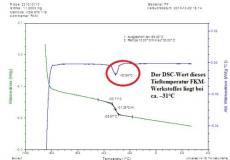

This calorimetric test identifies the thermodynamic glass transition of elastomers, marking the shift from energy elasticity to entropy elasticity.

In applications where elastomers are used as bumpers, minimizing self-heating resulting from absorbed energy is essential.

To prevent static electricity buildup or electrochemical degradation

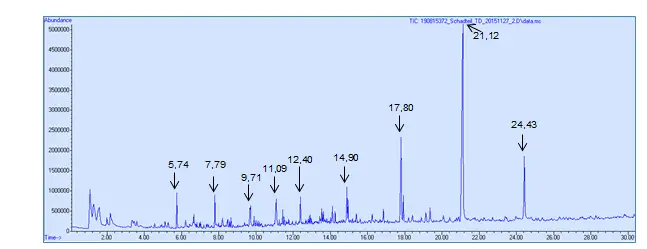

The analysis method with the highest resolution for obtaining indications of the ingredients present in elastomer samples. A sample size as small as 1 mg is adequate for this purpose.

For the O-Ring Prueflabor Richter the failure analysis of elastomeric seals is one of its core competences.

All items marked with a * are required.

.jpg)