FEP Encapsulated O-rings are high-quality seals made from fluorinated ethylene propylene (FEP), a specialized fluoropolymer known for its excellent chemical resistance and wide temperature range. Similar to PTFE (Teflon), FEP offers enhanced elasticity and deformability, making it ideal for demanding applications. These O-rings are extensively used in the chemical and pharmaceutical industries, where they withstand aggressive chemicals and temperatures ranging from -200°C to +200°C. FEP Encapsulated O-rings maintain their integrity and sealing performance even under extreme conditions, making them a reliable choice for critical applications. Click here for more information about FEP O-rings.

FEP Encapsulated O-rings are seals made from fluorinated ethylene propylene (FEP), a high-quality polymer known for its excellent chemical resistance and temperature tolerance. FEP is a fluoropolymer similar to PTFE (Teflon) but with improved elasticity and deformability. FEP O-rings are used in applications where extreme chemical resistance and a wide temperature range are required, often in the chemical and pharmaceutical industries and in the transport of aggressive chemicals.

The main advantages of FEP O-rings are their inertness to most chemicals, including acids, bases, solvents, and fuels. They maintain their integrity and sealing performance in temperatures ranging from -200°C to +200°C, making them suitable for cryogenic applications as well as high-temperature processes. FEP Encapsulated O-rings are also FDA-approved for use in food and beverage applications where chemical resistance and safety are crucial. The flexibility and sealing capability of FEP O-rings make them a versatile choice for demanding industries.

FEP (Fluorinated Ethylene Propylene) encapsulated O-rings offer several benefits that make them suitable for critical sealing applications. A key advantage is their excellent chemical resistance to a wide range of aggressive chemicals, acids, bases, and solvents. The FEP encapsulation protects the base O-ring, thus extending its lifespan and performance in demanding chemical environments.

Additionally, FEP O-rings provide a low coefficient of friction, making them easy to install and use in dynamic applications. They withstand high temperatures and maintain their sealing performance across a broad temperature range.

FEP Encapsulated O-Rings are also suitable for use in food and pharmaceutical applications due to their FDA approval and biological inertness. In summary, the combination of chemical resistance, temperature resistance, and reliable sealing makes FEP-encapsulated O-rings a valuable choice for various industries.

FEP Encapsulated O-Rings are widely used in critical sealing applications due to their unique properties. The FEP encapsulation provides an additional protective layer and enhances the chemical resistance of the O-ring, making it suitable for use with aggressive chemicals, acids, bases, and solvents.

The applications of FEP Encapsulated O-Rings are diverse and include laboratory equipment, chemical processing plants, semiconductor manufacturing, medical equipment, and food processing. They are used in systems where reliable sealing is essential and exposure to extreme temperatures and chemical environments may occur.

FEP O-rings offer excellent sealing performance and durability in demanding conditions, making them a popular choice in various industries where chemical resistance and reliability are critical.

Although FEP (Fluorinated Ethylene Propylene) encapsulated O-rings offer many advantages, there are also some drawbacks to consider. One significant drawback is that FEP O-rings may be more sensitive to mechanical stress and wear compared to some other sealing materials. The FEP encapsulation can be damaged with prolonged exposure to abrasive or aggressive environments, leading to reduced sealing performance.

Additionally, FEP Encapsulated O-Rings may be more expensive than standard O-rings due to the additional production process required to apply the FEP encapsulation. This can impact project costs, especially in large-scale applications.

Finally, FEP O-rings are not suitable for steam or high-pressure applications as the FEP encapsulation may be prone to delamination under such conditions. It is important to evaluate the compatibility of FEP Encapsulated O-Rings with specific applications before their use.

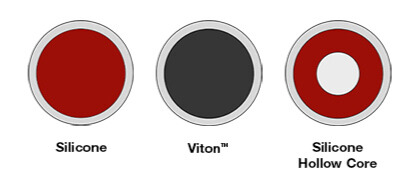

The main difference between an FEP Encapsulated O-Rings Viton O-ring and an FEP Encapsulated Silicone O-ring lies in the material they are made of and their specific properties.

An FEP Viton O-ring combines fluorinated ethylene propylene (FEP) with Viton (FKM), a fluoroelastomer known for its excellent chemical resistance to oils, fuels, and chemicals. FEP Viton O-rings withstand high temperatures and maintain their sealing performance in aggressive chemical environments.

On the other hand, an FEP Silicone O-ring is made from FEP-coated silicone rubber. Silicone rubber offers good flexibility, thermal stability, and is suitable for higher temperatures than ordinary rubber materials. The FEP coating enhances chemical resistance and adds an extra layer of protection against aggressive media.

In general, it is important to choose the right type of O-ring based on the specific chemical environment and temperature requirements of the application.